Rendering and CAD model: Mary Suttle

by Mary Suttle, Keith Costa, Lu Pan, and Aaron Brinks / Research, manufacture-ready CAD model, project plan, and sketches by Mary Suttle

About

Clidro is a waterproof drone designed to be used by surfers to capture their most epic moments out on the water. Clidro’s small size and low weight allows the drone to follow surfers wherever the waves take them. The motion tracking technology and convenient surfboard mounted charging cradle allows for surfers of all levels to take high quality and dynamic footage.

What is so different about this drone?

For surfers looking to gain a sponsorship or following, having high quality video footage is vital. The surf world (like other high-performance sports) is driven by visuals that help sell the lifestyle. Surf shops, brands, and followers need proof of your abilities in order to buy into your brand. For a young surfer just starting off or a hobby surfing looking to go pro, hiring a videographer or investing in an expensive camera is not an option.

The Current Solutions

There is a gap in the market for an easier to use drone in the mid-price range and high performance drones in the low price category. Realistically, the quality of drone we would be looking to create would eliminate the low cost high-performance drone. The high-performance aspect requires higher quality components than the low price point drones.

The high-performance drones that can withstand high stress environments, track a subject, and capture high quality video are high price with a steep learning curve. These drones are usually used for industrial or commercial applications. The lower priced drones are usually intended for less experienced users or hobbyists rather than for capturing video of a high-performance sport such as surfing. There is a gap in the market for a mid-tier drone with easy to learn controls that can capture high-quality video.

Necessary Design Features

Concept Development

Surfers would need to use a drone with very few features. They would need a drone that can track a subject, is waterproof, and is nimble. With this in mind, we began exploring concepts for the external housing and style of drone for our surfing drone. We determined a quadcopter design would allow for the most maneuverability and the slimmest profile.

The Clidro Surf Drone

Rendering: Aaron Brinks / CAD model: Mary Suttle

The Clidro surf drone is a quadcopter drone with a slim profile. The low weight and 4 propellers allow for quick turns and maneuverability while following a surfer on the water. The drone features a high definition camera that can capture every epic moment on the water. The drone can be recharged on a solar powered induction charging cradle that can easily be mounted on the surfboard. This charging cradle also functioned as the tracking point for the drone to follow while filming. The components and materials were carefully selected to reduce weight and increase performance.

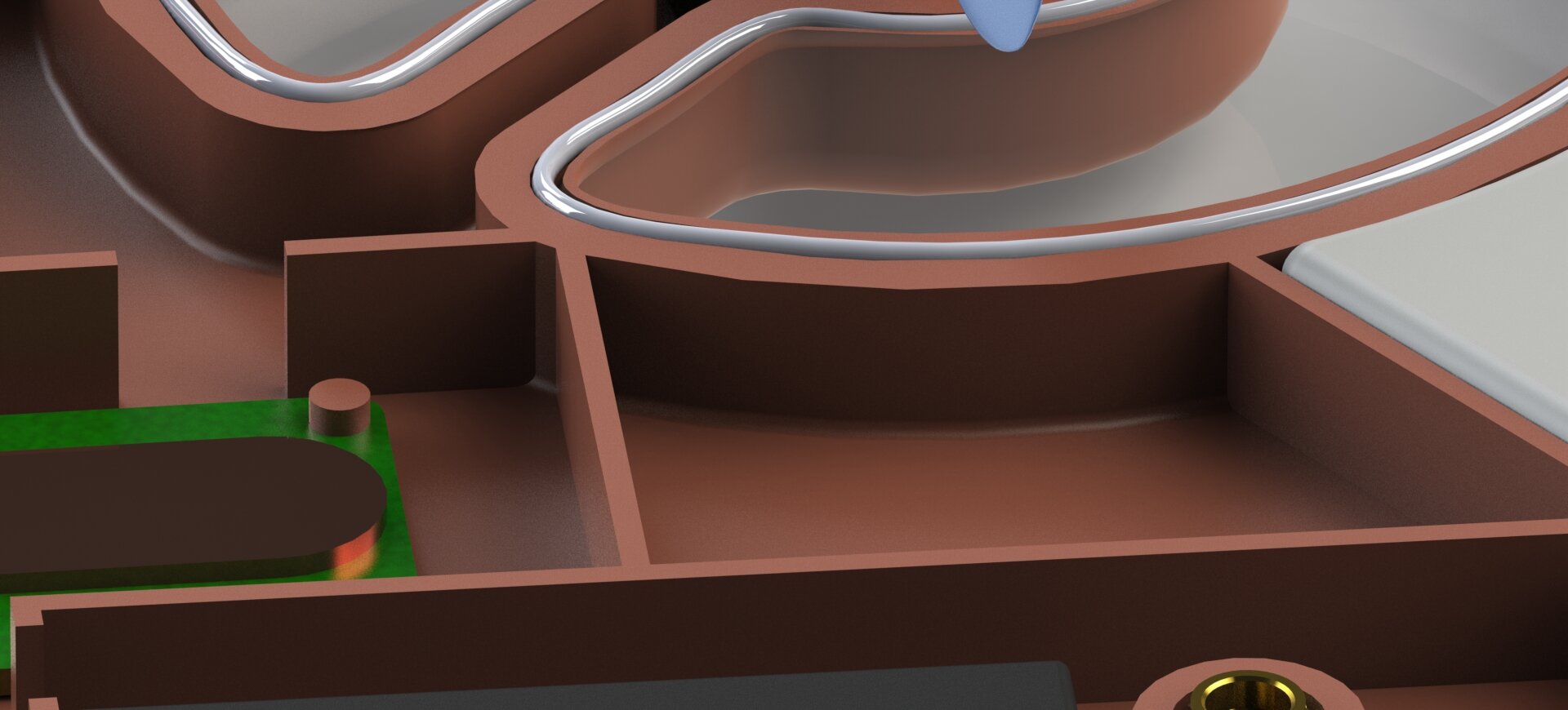

Drone Components

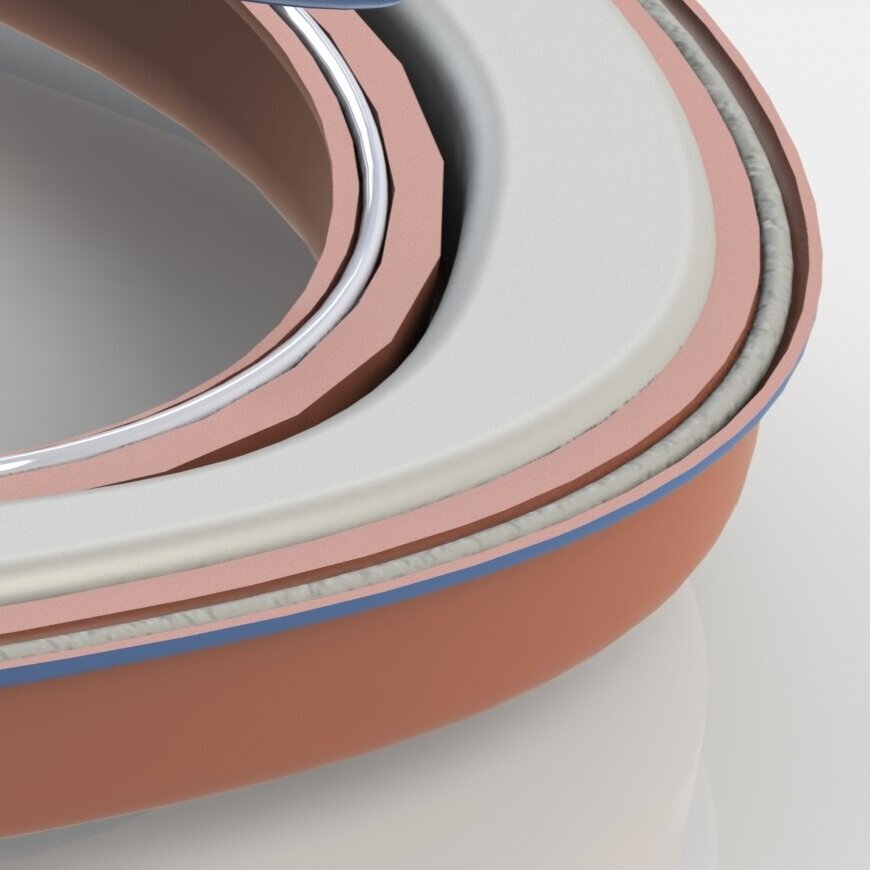

The internal components are encased in an ABS plastic housing. ABS has good impact resistance, is inexpensive, has a low weight to strength ratio, and has a good appearance when molded. ABS has low chemical reactivity, is ideal for saltwater exposure, and is resistant to UV damage. ABS can withstand high temperatures which is vital when housing electronics and with direct exposure to heat for extended periods of time.

The design features four waterproof brushless motors which are more durable than typical motors. In case the drone fails on the water, custom molded floats ensure the drone will float and not sink to the bottom of the ocean. The battery is connected to a solar charge controller and induction charging coil. This allows for the drone to wirelessly charge on-the-go. Induction charging was chosen to allow for quick recharges in between sets. The drone did not need to be in flight for very long, so a slightly slower charging method was acceptable. The induction charging allowed for the drone to be watertight at all time.

Design for Manufacturability

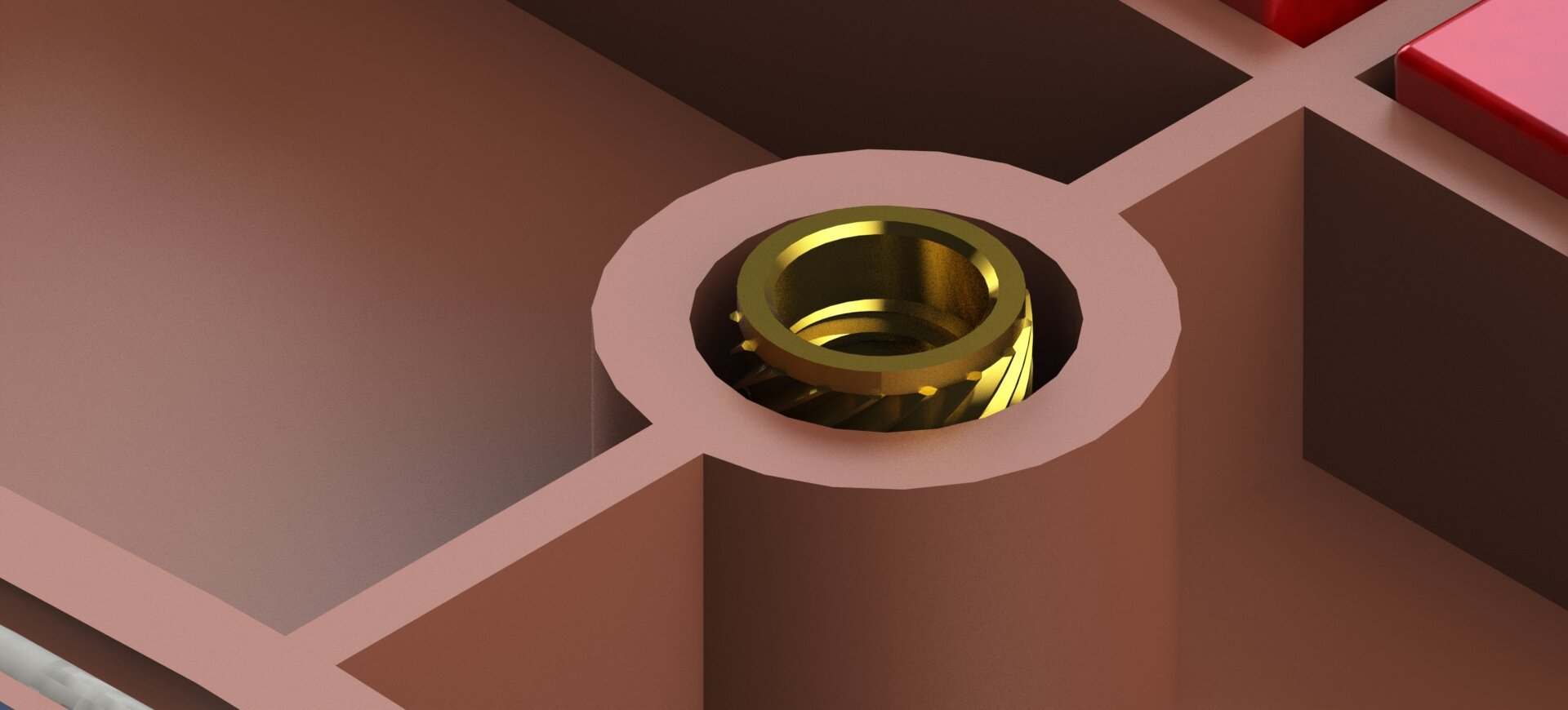

Many electronic devices and drones are permanently and ultrasonically welded, but we wanted the drone components to be accessible for repair. In order for the drone to be opened up and repaired, a silicone custom o-ring was added around the entire perimeter, the propeller mountings, and the screw openings. As the external housing is screwed together, the o-ring is compressed and creates a watertight environment that protects the electronic components. The small HD camera in the front is also protected by an additional o-ring.

Components that needed to be permanently attached were secured via heat staking. The threaded ultrasonic inserts were chosen to make sure the screws can tighten the housing together very securely.

Rendering and CAD model: Mary Suttle

Mary Suttle/Clidro/2017